Когда речь идет о пожарной безопасности, даже самая незначительная деталь может иметь огромное значение. Выбор правильного производитель противопожарных клапанов это не просто ценник или быстрая доставка - это защита жизни, имущества и душевного спокойствия. Пожарные клапаны - это молчаливые стражи в каждой системе пожаротушения, готовые контролировать поток воды и предотвращать разрастание катастрофы.

Однако не все производители одинаковы. Одни ставят во главу угла инновации и сертификаты безопасности, а другие гонятся за дешевизной производства, не заботясь о долгосрочной надежности. Именно здесь и происходит "зеленая революция" в производстве, сочетающая безопасность с устойчивостью.

Подумайте сами: стали бы вы доверять пожарному клапану, изготовленному без соблюдения строгих стандартов испытаний? Или вы будете чувствовать себя в большей безопасности с клапаном, имеющим международные сертификаты и проверенный годами опыт? Ответ очевиден, и в этой статье мы подробно рассмотрим все, что вам нужно знать о выборе правильного производителя.

Что такое производитель противопожарных клапанов?

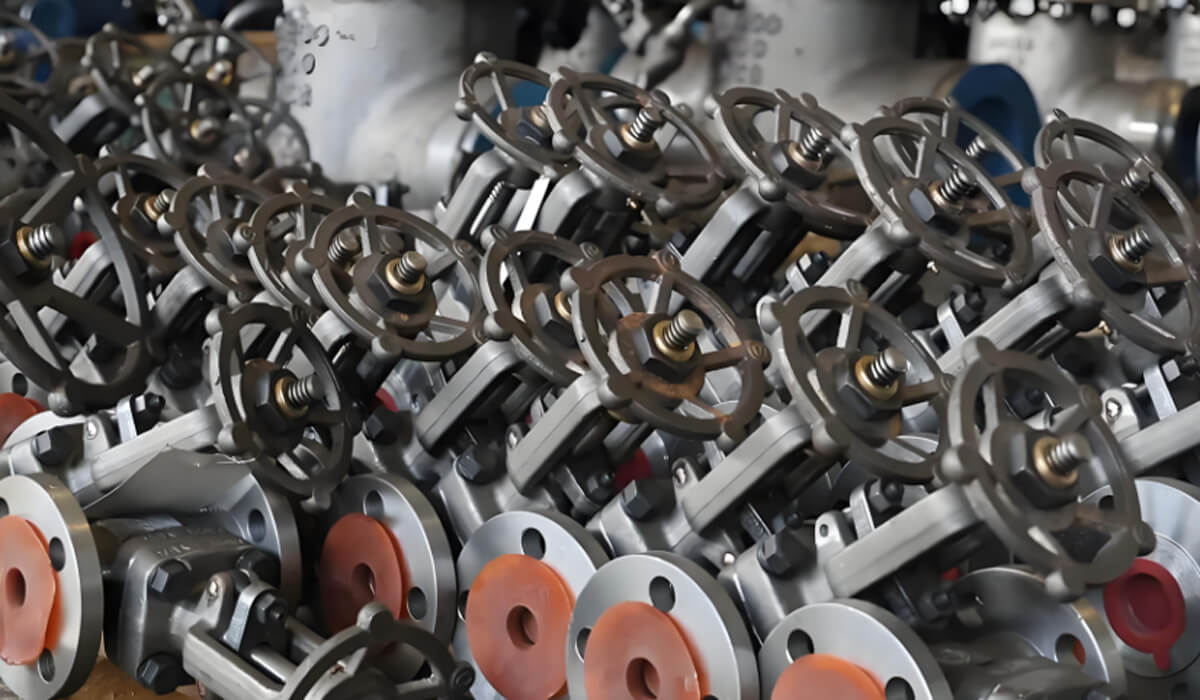

A производитель противопожарных клапанов компания, специализирующаяся на разработке, производстве и испытании клапанов, используемых в системах противопожарной защиты. Эти клапаны регулируют подачу воды или средств пожаротушения в спринклерах, гидрантах и стояках. Их роль может показаться технической, но на самом деле это инструменты для спасения жизни.

Производители должны найти баланс между долговечностью, точностью и надежностью. Например, неисправный клапан может задержать подачу воды во время пожара, что приведет к гибели людей и материальным потерям. С другой стороны, хорошо спроектированный клапан, изготовленный в соответствии со строгими промышленными стандартами, может мгновенно сработать и локализовать пожар в течение нескольких мгновений.

На всех этапах производства - от литья и механической обработки до испытаний под давлением - необходимо соблюдать международные нормы пожарной безопасности. Поэтому выбор авторитетного производителя - не просто разумное решение, а обязательное.

Почему выбор правильного производителя противопожарных клапанов имеет значение

Скажем прямо: огонь не прощает ошибок. Устанавливать некачественные клапаны или заказывать их у ненадежных производителей - все равно что играть с огнем, в прямом смысле слова.

Правильный производитель противопожарных клапанов гарантии:

- Соответствие нормам безопасности (NFPA, ISO, CE).

- Долговечность при высоком давлении-Клапаны, которые не выходят из строя под нагрузкой.

- Душевное спокойствие Знайте, что ваша система будет работать, когда она вам больше всего нужна.

Думайте об этом как о страховке: здесь не стоит срезать углы. Производитель, который инвестирует в качество, гарантирует меньшее количество поломок, меньшие затраты на обслуживание и большую уверенность в вашей системе противопожарной защиты.

Ключевые качества, которые следует искать в производителе противопожарных клапанов

Сравнивая производителей, обратите внимание на определенные качества:

- Сертификация и аккредитация - UL, FM, ISO, CE не подлежат обсуждению.

- Записи о пройденном пути - Многолетний опыт и репутация на рынке пожарной безопасности.

- Обеспечение качества - Протоколы жестких испытаний, включая гидростатические испытания и испытания на выносливость.

- Инновации - Интеграция экологически чистых процессов и интеллектуальных технологий.

- Послепродажная поддержка - Гарантийное покрытие, обучение и наличие запасных частей.

Если производитель не справляется с этими задачами, это тревожный сигнал.

Стандарты и сертификаты в производстве противопожарных клапанов

Никто не хочет рисковать безопасностью. Именно поэтому сертификаты служат вам "Северной звездой" при выборе производителя. К наиболее надежным сертификатам относятся:

- UL (Underwriters Laboratories) - Признан за строгие испытания пожарного оборудования.

- FM (Factory Mutual) - Основное внимание уделяется снижению рисков и надежности пожарных систем.

- ISO 9001 И ISO 14001 - Управление качеством и соблюдение экологических норм.

- Маркировка CE - Обязательное условие на европейских рынках для обеспечения безопасности и надежности.

- Соответствие требованиям NFPA - Обеспечивает соблюдение правил пожарной безопасности Национальной ассоциации пожарной безопасности.

Всегда проверяйте эти сертификаты перед подписанием сделки.

Глобальный и локальный производитель противопожарных клапанов

Выбор между местным и международным поставщиком часто бывает непростым.

Мировые производители:

- Более широкие сертификаты.

- Передовые научно-исследовательские мощности.

- Международная репутация.

Местные производители:

- Быстрая доставка и обслуживание.

- Облегчение общения и посещения объектов.

- Часто более экономичны.

Идеальный выбор часто зависит от масштаба проекта, бюджета и нормативной базы.

Как сравнить производителей пожарных клапанов

Если вы сталкиваетесь с несколькими поставщиками, вот краткий контрольный список для сравнения:

| Фактор | Почему это важно | Что спросить |

|---|---|---|

| Цена | Обеспечьте ценность, а не дешевое качество | Является ли ценообразование прозрачным? |

| Качество | Жизнеутверждающая надежность | Какие процедуры тестирования вы используете? |

| Гарантия | Долгосрочная поддержка | Сколько лет покрытия? |

| Материалы | Долговечность под давлением | Используете ли вы коррозионно-стойкие металлы? |

| Репутация | Надежность | Можете ли вы поделиться рекомендациями клиентов? |

Боковой анализ сделает ваш выбор более четким.

Распространенные ошибки при выборе производителя противопожарных клапанов

Многие покупатели натыкаются на те же ловушки:

- Приоритет цены над безопасностью - Несколько долларов, сэкономленных сегодня, могут стоить тысячи в будущем.

- Игнорирование сертификации - Несертифицированные клапаны могут не соответствовать законодательным стандартам.

- Уделяя большое внимание послепродажному обслуживанию - Поддержка не менее важна, чем покупка.

- Не проверяет рекомендации - Отзывы и примеры из практики говорят о многом.

Избегайте этих подводных камней, и вы уже будете впереди.

Будущие тенденции в производстве противопожарных клапанов

Индустрия противопожарной защиты не застряла в прошлом. На самом деле производители внедряют инновации, как никогда раньше:

- Интеллектуальные клапаны - Датчики и системы с поддержкой IoT для удаленного мониторинга.

- Экологически чистые материалы - Сплавы, не содержащие свинца, и металлы, пригодные для вторичной переработки.

- Автоматизация в производстве - Последовательность и меньшее количество человеческих ошибок.

- Энергоэффективность - Экологически чистые заводы, меньший углеродный след.

Эти тенденции указывают на более безопасную и устойчивую противопожарную защиту.

Зеленая революция: Как выбрать производителя противопожарных клапанов

Теперь перейдем к самому главному: зеленой революции. Переход к устойчивой пожарной безопасности меняет методы работы производителей. Современный производитель противопожарных клапанов теперь оценивают не только по безопасности и производительности, но и по экологичности.

- Устойчивое производство - Сокращение количества отходов, экологически чистые материалы, энергоэффективные фабрики.

- Зеленые сертификаты - Соответствие стандарту ISO 14001, экологические сертификаты, инициативы по снижению выбросов углекислого газа.

- Ответственное сорсинг - Этичные закупки сырья.

- Инновации с целью - Интеллектуальные клапаны минимизируют расход воды, снижая воздействие на окружающую среду.

Другими словами, лучший выбор - это не только самый безопасный, но и самый ответственный.

Вопросы, которые нужно задать производителю противопожарных клапанов перед покупкой

Прежде чем поставить свою подпись, задайте эти важные вопросы:

- Можете ли вы предоставить сертификаты UL, FM или CE?

- Какие виды гарантии вы предлагаете?

- Как вы справляетесь с отзывами или дефектами продукции?

- Проводите ли вы обучение обслуживающего персонала?

- Можете ли вы изготовить клапаны для уникальных пожарных систем?

- Как вы обеспечиваете соблюдение экологических норм на своем производстве?

Ответы покажут, действительно ли производитель заслуживает доверия.

Тематическое исследование: Уроки успешных проектов по пожарной безопасности

В Дубае высотная коммерческая башня столкнулась с разрушительной угрозой пожара. Благодаря клапанам, поставленным сертифицированным производителем, противопожарная система сработала безупречно - сработала в считанные секунды и сдержала пламя.

С другой стороны, на одном из складов в Азии произошел пожар, когда несертифицированные клапаны вышли из строя под давлением. Ущерб был катастрофическим и обошелся в миллионы. Контраст очевиден: сделайте правильный выбор, и вы сохраните жизни и имущество. Неправильный выбор - и последствия могут быть катастрофическими.

Вопросы и ответы

Что делает производитель противопожарных клапанов?

Они разрабатывают, производят и испытывают противопожарные клапаны, используемые в гидрантах, спринклерах и системах пожаротушения.

Почему сертификация важна при выборе производителя противопожарных клапанов?

Сертификация гарантирует соответствие продукции нормам безопасности и международным стандартам, что снижает риск отказа.

Как сравнить различные производители противопожарных клапанов?

Посмотрите на сертификаты, проверку качества, гарантии, прозрачность цен и отзывы клиентов.

Надежны ли экологичные противопожарные клапаны?

Да, устойчивые клапаны могут быть такими же надежными, если они соответствуют строгим стандартам пожарной безопасности.

Что лучше - выбрать местного или мирового производителя противопожарных клапанов?

У обоих вариантов есть плюсы и минусы: глобальный предлагает передовые разработки, а местный - более быстрое обслуживание.

Каково будущее производства противопожарных клапанов?

Будущее - за умными клапанами с поддержкой IoT и экологичными методами производства.

Заключение: Разумный выбор в пользу пожарной безопасности

Выбор правильного производитель противопожарных клапанов это не просто деловое решение - это решение, спасающее жизнь. Уделяя особое внимание сертификации, устойчивости, качеству и послепродажному обслуживанию, вы гарантируете, что ваша система противопожарной защиты выдержит испытание временем.

Поскольку "зеленая революция" набирает обороты, выбор производителя, который поддерживает устойчивое развитие и обеспечивает бескомпромиссную безопасность, - самый разумный выбор, который вы можете сделать. В конце концов, пожарная безопасность - это не срезание углов, а создание доверия и обеспечение будущего.