Fire hydrants are one of those things we often walk past without giving them much thought—until we need them. In every building or community, proper fire protection isn’t just a legal requirement; it’s a life-saving necessity. When people compare Indoor Fire Hydrant VS Outdoor Fire Hydrant, most assume they work the same way. But in reality, their roles, design, installation requirements, and performance can differ quite a bit. Understanding those differences helps building owners, contractors, engineers, and even homeowners make smarter safety decisions.

Over the years, I’ve worked closely with firefighting equipment manufacturers, installation teams, and compliance officers. Through this experience, I’ve seen how picking the wrong hydrant type—or installing it incorrectly—can slow down fire response and even put lives at risk.

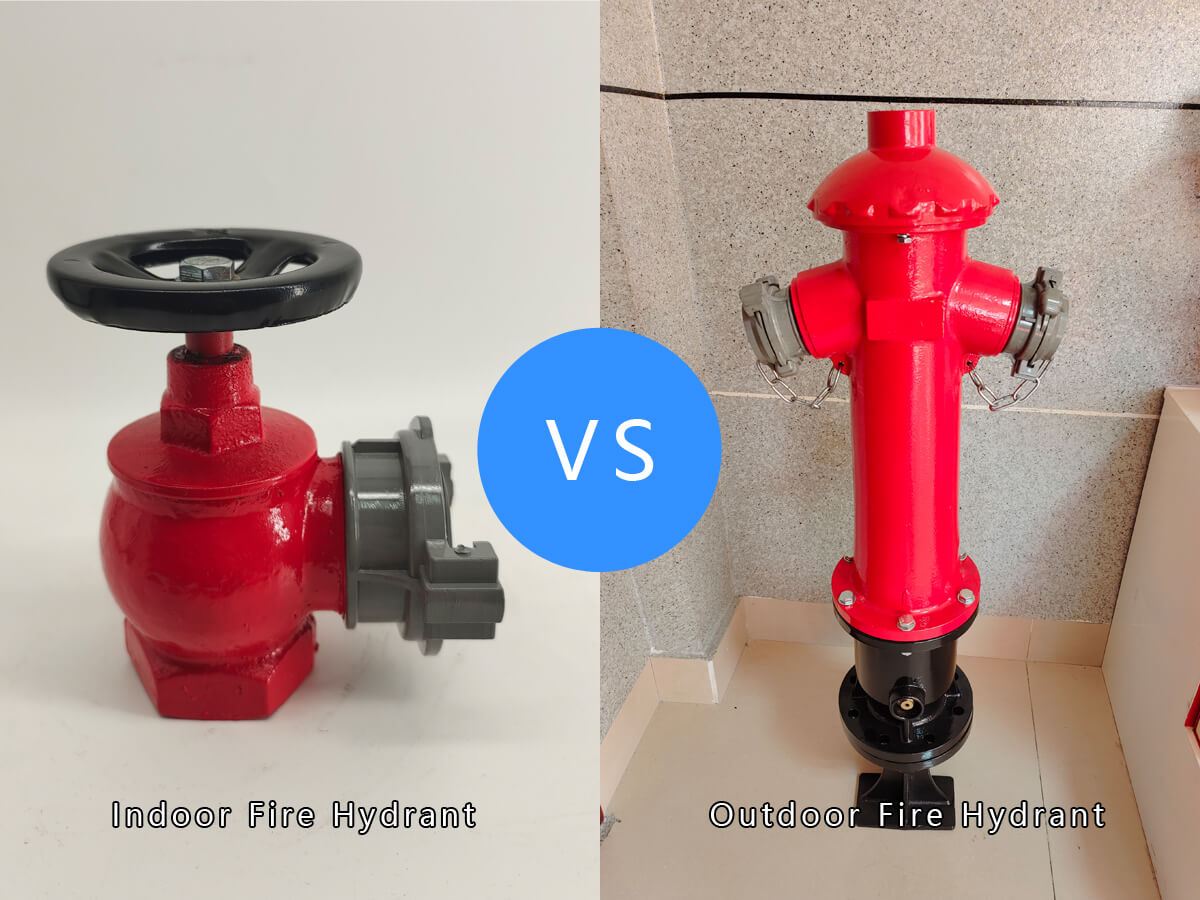

Indoor Fire Hydrant VS Outdoor Fire Hydrant

When comparing Indoor Fire Hydrant VS Outdoor Fire Hydrant, the first step is understanding their purpose. Even though both supply water for firefighting, they’re designed for different situations.

Indoor hydrants are installed inside buildings—commercial towers, hotels, schools, factories—where firefighters need quick access to a pressurized water source. These systems connect to the building’s internal piping and are often paired with hose reels and fire cabinets.

Outdoor hydrants, on the other hand, stand outside on streets, sidewalks, parking lots, industrial yards, and open areas. They connect to a municipal or private water supply network and must stay accessible for fire trucks and emergency responders.

Why Both Are Needed?

Indoor hydrants fight fires inside a structure before they spread. Outdoor hydrants support firefighting operations from outside, allowing engines to maintain high water flow.

Quick Comparison Table

| Feature | Indoor Fire Hydrant | Outdoor Fire Hydrant |

|---|---|---|

| Location | Inside buildings | Outdoors |

| Water Source | Internal building piping | Municipal or site water network |

| Protection | Indoor fire suppression | External fire operation support |

| Design | Compact, cabinet-mounted | Ground-mounted, exposed |

| Flow Rate | Moderate | High-volume |

| Maintenance | Indoor checks | Weather-proof inspections |

Both systems are crucial, and their effectiveness increases when used together during emergencies.

Key Features of Indoor Fire Hydrants

Indoor fire hydrants are built with several specific features that make them suitable for enclosed environments.

1. Protected Installation

Since they’re placed in corridors, staircases, and fire control rooms, indoor hydrants include cabinets or enclosures to prevent damage and keep them visible.

2. Pressure-Controlled Design

Many indoor hydrants use pressure-reducing valves, especially in high-rise buildings where water pressure can be extremely high. Without these valves, connecting a hose could become dangerous.

3. Easy Hose Access

Most indoor systems have hose reels, nozzles, and fire extinguishers nearby. Trained staff can begin suppression work even before firefighters arrive.

4. Ideal for Early-Stage Fires

Indoor fire hydrants are designed to tackle fires while they’re still small. Quick action can prevent major damage.

5. Supports Firefighter Operations

Firefighters rely on indoor hydrants to navigate large structures and maintain water flow on upper floors.

Key Features of Outdoor Fire Hydrants

Outdoor hydrants stand up against weather, traffic, and long-term exposure. Their features reflect that.

1. Durable Construction

They’re typically made from ductile iron or brass with corrosion-resistant coatings. Some models even include frost-proof systems for cold regions.

2. High Flow Capacity

Outdoor hydrants must deliver powerful water streams—sometimes hundreds of gallons per minute. Fire trucks depend on this volume.

3. Easily Accessible

They’re installed in open areas where firefighters can connect hoses or pump trucks quickly. Adequate clearance is required by fire codes.

4. Connection to Municipal Supply

Outdoor hydrants often connect directly to the city’s water system, ensuring stable and high-volume pressure.

5. Designed for Longevity

With proper maintenance, outdoor hydrants can last 25–50 years, sometimes even longer.

Material, Design & Installation Differences

Indoor and outdoor hydrants may look similar in pictures, but their construction is completely different in practice.

Materials Used

| Component | Indoor Hydrant | Outdoor Hydrant |

|---|---|---|

| Valve Body | Stainless steel / brass | Ductile iron / cast iron |

| Connectors | Brass | Bronze or cast iron |

| Cabinet | Powder-coated steel | Not applicable |

| Gaskets | Rubber | EPDM or nitrile (weather-resistant) |

Design Differences

- Indoor models focus on compact, tidy layouts.

- Outdoor models prioritize ruggedness and frost protection.

- Outdoor hydrants offer multiple hose ports.

- Indoor hydrants use a single valve with a hose.

Installation Requirements

- Indoor hydrants must meet building fire codes (e.g., spacing, cabinet height).

- Outdoor hydrants need ground clearance, base support, and hydrant markers.

- Underground piping must meet local water authority standards.

Performance Comparison of Indoor Fire Hydrant VS Outdoor Fire Hydrant

Performance is where the differences really show.

Water Pressure & Flow

Outdoor hydrants almost always deliver higher flow. Fire trucks can boost the pressure even more using pumps.

Indoor hydrants, however:

- Provide controlled pressure.

- Stabilize flow for safe indoor use.

Response Time

Indoor hydrants:

- Allow faster action within buildings.

- Are accessible to trained staff instantly.

Outdoor hydrants:

- Require firefighters to arrive on-site.

- Support sustained operations.

Temperature Resistance

Outdoor hydrants must survive heat, freezing, rain, UV exposure, and more. Indoor hydrants stay protected from harsh conditions.

Safety Standards & Compliance Requirements

Depending on your country, the standards may vary. Some widely recognized ones include:

- NFPA 14 – Standard for standpipe and hose systems

- NFPA 24 – Installation of private fire service mains

- EN 671 – Indoor hydrant systems

- ISO fire protection standards

Local fire departments often provide installation codes and inspection rules. Following these prevents accidents and ensures hydrants work when needed.

You can find additional guidance at:

External Resource: https://www.nfpa.org

Maintenance Requirements for Both Types

Regular maintenance helps hydrants work properly during emergencies.

Indoor Hydrant Maintenance

- Monthly cabinet inspection

- Valve lubrication

- Hose pressure test

- Seal replacement

Outdoor Hydrant Maintenance

- Lubricating the stem

- Checking for leaks

- Painting against corrosion

- Clearing vegetation

- Winterizing (in cold climates)

Fire departments worldwide recommend annual flow tests for all hydrants.

Cost, Lifespan & Application Scenarios

| Category | Indoor Hydrant | Outdoor Hydrant |

|---|---|---|

| Installation Cost | Moderate | High |

| Maintenance Cost | Low | Moderate |

| Lifespan | 15–30 years | 25–50 years |

| Best Applications | Buildings, malls, airports | Streets, factories, community zones |

The right choice depends on the location, risk level, and water supply.

Indoor Fire Hydrant VS Outdoor Fire Hydrant in Emergency Response

During an actual fire, the difference between indoor and outdoor hydrants becomes even clearer.

Indoor Hydrants

- Provide immediate access

- Allow building occupants or security staff to respond

- Reduce the chance of fire spreading before firefighters arrive

Outdoor Hydrants

- Enable fire trucks to refill quickly

- Allow firefighters to operate multiple hoses

- Support long-duration firefighting

Both systems work together to create a faster, safer, more strategic response.

Choosing the Right Hydrant for Your Property

Here are the key factors to consider:

- Building Size

Large buildings require indoor hydrants on every floor. - Fire Risk

Warehouses and industrial areas benefit from powerful outdoor hydrants. - Water Source

Outdoor hydrants need strong municipal supply. - Climate

Cold regions need frost-proof outdoor hydrants. - Budget

Indoor hydrants cost less upfront. - Accessibility

Outdoor hydrants must remain clearly visible at all times.

Conclusion

Understanding the difference between Indoor Fire Hydrant VS Outdoor Fire Hydrant helps ensure your building or community is properly protected. Indoor hydrants provide quick, controlled access for early-fire action, while outdoor hydrants deliver the heavy-duty water flow needed for full-scale firefighting operations. When both are installed and maintained correctly, they form a powerful, life-saving fire protection network.

Choosing the right hydrant type isn’t just a compliance issue—it’s a smart investment in safety, long-term property protection, and peace of mind.

FAQs

What is the main difference between indoor and outdoor fire hydrants?

Indoor hydrants are installed inside buildings for quick response, while outdoor hydrants are placed outside for firefighters and truck operations.

Do indoor fire hydrants need pressure-reducing valves?

Yes, especially in high-rise buildings where internal pressure can be dangerously high.

Can I use an outdoor hydrant inside a building?

No. Outdoor hydrants are too large, too powerful, and not suitable for indoor installation.

How often should hydrants be inspected?

Most authorities require annual inspections and monthly visual checks.

Are outdoor fire hydrants frost-proof?

Many models are. Fire hydrants in cold regions must be frost-resistant to prevent freezing.

Which one is better for industrial zones?

Outdoor hydrants are generally better because they offer higher flow and easy access for fire trucks.