Fire emergencies can happen at any time, and having a reliable fire hydrant system plays a major role in protecting lives, buildings, and property. Fire hydrants are one of the oldest and most trusted fire protection tools used around the world. They allow firefighters to access water quickly during emergencies, making them a key part of every fire safety plan. This guide explains all the common Types of Fire-Fighting Hydrant in simple, clear language, along with insights from real industrial and urban firefighting experience.

1. Introduction to Fire-Fighting Hydrant Systems

Fire-fighting hydrant systems are fixed installations designed to supply water instantly when a fire breaks out. These systems are commonly found in residential buildings, factories, warehouses, commercial centers, and public places. Their main goal is to provide a continuous water flow at sufficient pressure so that fires can be controlled quickly.

Hydrant systems differ depending on the climate, local fire codes, and the type of building. Hot regions often use “wet” hydrants filled with water all the time, while cold regions need “dry” systems to prevent water from freezing. Hydrants also differ in size, shape, outlet type, and materials.

These differences are important because choosing the wrong hydrant can cause water supply failure during emergencies. Understanding the right type helps ensure safety and long-term reliability.

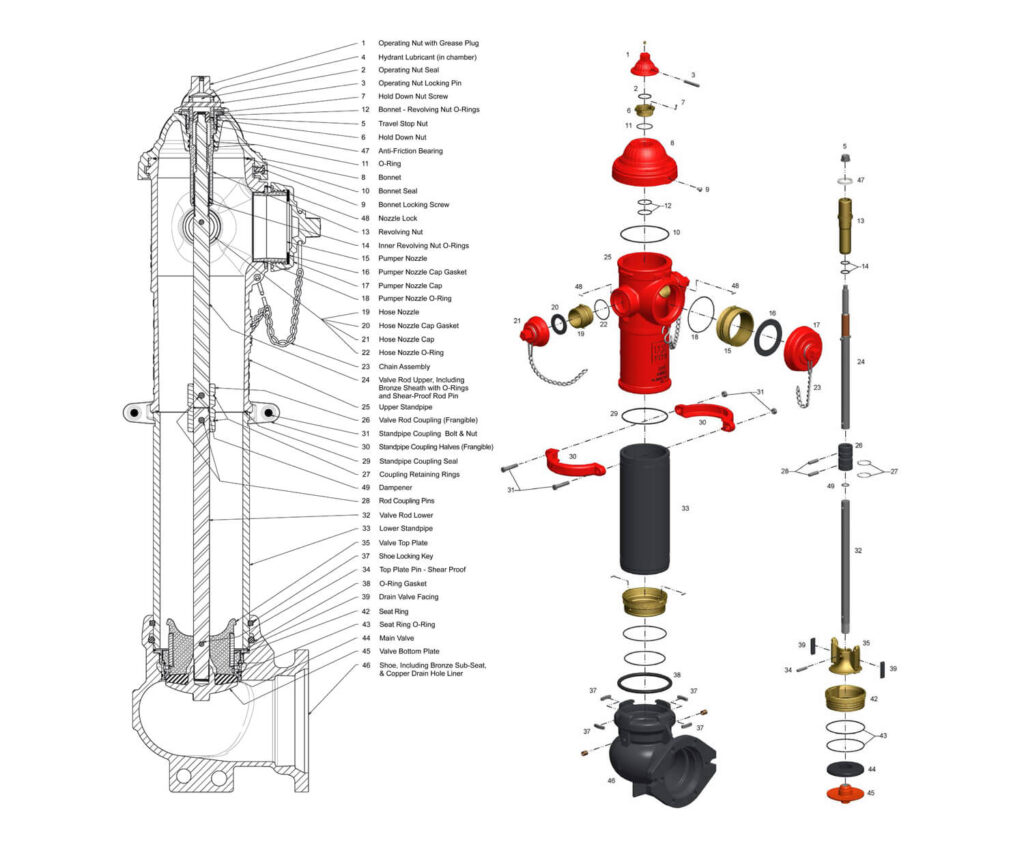

2. Understanding Fire Hydrant Components and Working Mechanism

A fire hydrant is more than just a red pipe. It is a carefully engineered system that includes:

- Hydrant Body

- Main Valve

- Hydrant Outlet or Nozzle

- Operating Nut or Wheel

- Seals and Rubber Gaskets

- Drain Valve (in some types)

- Water Supply Connection

How It Works

- Firefighters connect a hose to the outlet.

- They open the valve using a wrench or wheel.

- Water flows from the underground supply or storage tank.

- Pressure builds up and water is delivered to control the fire.

A hydrant must withstand high pressure, corrosion, weather, and heavy use. This is why materials like ductile iron, brass, and stainless steel are commonly used.

3. Types of Fire-Fighting Hydrant

This section explains all major hydrant types used worldwide. Each type is suited for different climates, building codes, and emergency requirements.

3.1 Wet Barrel Hydrants (Wet Riser Systems)

Wet barrel hydrants always contain water inside the barrel. They are ideal for hot climates where freezing does not occur. Each outlet on the hydrant has its own valve, making it easier to operate.

Features

- Water is always available

- Easy to maintain

- Good for quick firefighting response

- Common in Asia, the Middle East, and tropical areas

Wet barrel hydrants are cost-effective and widely used for commercial buildings, shopping malls, and industrial sites.

3.2 Dry Barrel Hydrants (Dry Riser Systems)

Dry barrel hydrants are designed for regions with freezing temperatures. In these hydrants, water sits below the frost line and enters the barrel only when the main valve is opened.

Key Benefits

- Prevents freezing and cracking

- Suitable for Europe, Northern USA, Canada, China’s colder regions

- Long service life

Dry barrel hydrants have more parts, so they require more maintenance, but they are essential in cold climates.3.3 Standpost Hydrants (Post-Type Hydrants)

These are upright hydrants installed above ground. Firefighters can instantly connect hoses to them.

Advantages

- Easy visibility

- Fast access during emergencies

- Reliable for outdoor locations

These are common in industrial parks, ports, airports, and factory complexes.

3.4 Underground Hydrants (Flush-Type Fire Hydrants)

Underground hydrants are installed below ground with only a small surface lid visible. They are suitable for places where above-ground hydrants may block traffic or affect aesthetics.

Applications

- Shopping streets

- Public plazas

- Airports

- Parking areas

Although less visible, they are safe from accidental damage and vandalism.

3.5 Pillar Hydrants (Above-Ground Fire Hydrants)

Pillar hydrants are tall, visible, and easy for firefighters to locate quickly. They usually come in bright red, yellow, or blue colors.

Why They Are Popular

- Simple operation

- Strong water flow

- Visible at long distance

These are one of the most widely used hydrant types worldwide.

3.6 Hose Reel Hydrants (Fire Hose Systems)

These combine a hydrant valve with a hose reel, mostly installed indoors.

Best Use Cases

- Hotels

- Offices

- Schools

- Hospitals

They allow trained staff to control a fire before it spreads.

3.7 Landing Valves (Indoor Fire Hydrant Valves)

Landing valves are key parts of fire hydrant systems inside buildings. They help regulate water pressure and control flow.

Key Features

- Compact and durable

- Works with fire hose cabinets

- Supports fast response in indoor fires

They are common in high-rise apartments, malls, and factories.

3.8 Double Outlet Hydrants (Twin Outlet Fire Hydrants)

These hydrants come with two outlets, allowing multiple hoses to connect at once.

Advantages

- More water output

- Ideal for large-area fires

- Saves time during emergencies

These are common in big facilities like chemical plants, warehouses, and ports.

4. Applications of Different Fire Hydrant Types in Buildings and Industrial Areas

This section shows where each hydrant type is commonly used.

| Hydrant Type | Best Application |

|---|---|

| Wet Barrel | Hot climate cities, tropical regions |

| Dry Barrel | Cold climates, snowy regions |

| Underground | Urban streets, airports |

| Pillar Hydrant | Industrial zones, commercial districts |

| Double Outlet | Large warehouses, factories |

| Landing Valves | High-rise buildings |

| Hose Reel Hydrants | Indoor areas |

Understanding the right application ensures higher safety and compliance.

5. Installation Requirements and Safety Standards for Fire Hydrants

Fire hydrant installation must follow international fire codes such as:

- NFPA 24

- EN 14384

- ISO Standards

- Local fire department regulations

General Rules

- Install hydrants every 50–150 meters depending on the area

- Hydrant height should allow easy hose connection

- Must connect to reliable water mains

- Should withstand minimum 10–20 bar pressure

Proper installation ensures the system works when needed most.

6. Material Types Used in Fire Hydrant Manufacturing

Fire hydrants must handle pressure, heat, weather, and corrosion. Common materials include:

- Ductile Iron – strong and durable

- Cast Iron – cost-effective

- Brass – corrosion-resistant for valves

- Stainless Steel – used in high-end or corrosive environments

Using high-quality materials reduces leaks, rust, and long-term maintenance.

7. Fire Hydrant Inspection, Testing, and Maintenance Guide

Maintenance is essential to ensure hydrants work during emergencies. A typical inspection routine includes:

Monthly Check

- Visual inspection

- Lubrication of nuts and caps

Annual Test

- Flow test

- Pressure test

- Internal inspection

Neglecting maintenance can cause hydrants to fail during real fire incidents.

8. Comparing Fire Hydrant Types: Performance, Cost & Durability

| Hydrant Type | Performance | Cost Level | Durability |

|---|---|---|---|

| Wet Barrel | High | Medium | High |

| Dry Barrel | Very High | High | Very High |

| Underground | Medium | Medium | High |

| Pillar Hydrant | High | Medium | High |

| Double Outlet | Very High | High | High |

9. Common Challenges in Fire Hydrant Systems and How to Fix Them

Some common problems include:

- Low water pressure

- Rusting or corrosion

- Valve leakage

- Frozen hydrants

- Vandalism

- Blocked access

Solutions

- Regular flow testing

- Anti-corrosion coatings

- Winterizing hydrants

- Installing protective barriers

- Monthly cleaning

Good maintenance prevents system failures.

10. Expert Recommendations & Best Practices for Selecting Fire Hydrants

Experts suggest:

- Choose dry hydrants for cold areas

- Use wet hydrants for hot climates

- Install double outlet hydrants for large buildings

- Use underground hydrants in public spaces

- Always check certifications (NFPA, EN, ISO)

The right hydrant greatly improves firefighting capability.

11. 10 Tips on Choosing the Right Type of Fire-Fighting Hydrant

- Know your local climate

- Check water pressure requirements

- Choose certified hydrants only

- Match hydrant type with building needs

- Consider ease of operation

- Compare maintenance needs

- Verify materials

- Select visible colors for outdoor hydrants

- Choose double outlet for large facilities

- Follow local fire safety codes

12. FAQs About Types of Fire-Fighting Hydrant

1. What is the most common type of fire hydrant?

Pillar hydrants are the most common because they are easy to locate and use.

2. Which hydrant is best for cold regions?

Dry barrel hydrants are designed specifically for freezing climates.

3. How often should hydrants be tested?

At least once a year for full flow testing, but visual checks should be monthly.

4. What materials are best for hydrants?

Ductile iron and brass are widely used for durability and corrosion resistance.

5. Are underground hydrants safe?

Yes, they are protected against vandalism and accidental impact.

6. What is the difference between wet and dry hydrants?

Wet hydrants always contain water; dry hydrants stay empty until the valve is opened.

7. Can hydrants be used inside buildings?

Indoor systems use landing valves and hose reels instead of outdoor pillar hydrants.

8. Why do some hydrants have two outlets?

Double outlets allow more hoses to connect at once, improving firefighting speed.

9. How tall should a hydrant be?

Typically 600–1200 mm above ground, depending on local standards.

10. Can hydrants be customized?

Yes, many manufacturers offer special colors, materials, and outlet sizes.

Fire hydrants are essential for protecting lives and property during emergencies. Understanding the Types of Fire-Fighting Hydrant helps building owners, safety managers, and city planners choose the right system for their needs. From wet and dry barrel hydrants to underground and double outlet types, each hydrant plays a unique role in fire safety. By selecting the right system and following maintenance standards, you ensure reliable protection and long-term performance.